-40%

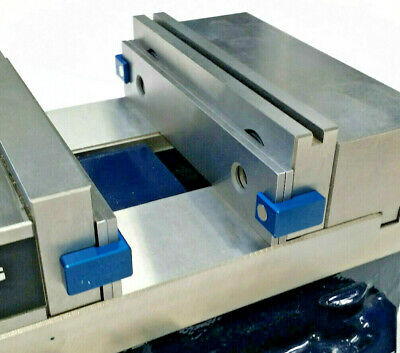

Cameron Sabretooth expanding chuck Mandrel internal workholding system 1.019"

$ 422.39

- Description

- Size Guide

Description

Cameron Sabretooth expanding chuck Mandrelinternal workholding system

There is 2x 1.019" Expanding collets as shown

Sabertooth expanding mandrels are a standard, in stock, internal workholding system. The Sabertooth system utilizes a slotted metal sleeve which has a series of tapers, or ramps. As the sleeve is pushed up, the tapers ( the slotted sleeve ) expands inside the part bore holding it securely for machining.

Sabertooth mandrels are available in sizes capable of holding internal part diameters from .500" to over 8.00" in diameter, in single or double length designs, with pull back or stationary collet movement. Utilizing the most rigid driving mechanism in the industry, Sabertooth mandrels can be used in heavy machining applications with no part movement.

The unique Sabertooth system features the following advantages:

-

Uniform expansion anywhere on the sleeve

-

Standard repetitive tolerances of .0008"

-

Minimal distortion of even thin walled parts

-

Pull back action compounds gripping pressure and ensures positive end location (also available with no pull back)

-

Double length and single length mandrels are stock and ready for immediate shipment

-

Available with between centers, and spindle type mountings

-

Available with manual or drawbar actuation

-

Additional features

Additional Features

Unique "saber-tooth" principle assures uniform expansion, eliminates bridging.

Standard repetitive tolerances .0008" TIR.

Minimizes distortion of parts. Ideal for precision grinding of thin-wall parts.

Securely grips short parts anywhere on sleeve.

Unique drive cage assures equalized torque transfer and unparalleled driving force.

Adjustable flange mount allows precise concentricity adjustments.

Sleeves are interchangeable on same size arbors. Manual or draw-bolt types are available.

Built-in "over-expansion stop" minimizes sleeve breakage.

Engineered "pull-back" action compounds gripping pressure and ensures positive end location. Stationary expansion is also available. This allows facing both ends of part in one operation.